Magnetostrictive sensors are Superior gadgets utilized to measure displacement, placement, and liquid ranges with significant precision and trustworthiness. These sensors function dependant on the principle of magnetostriction, where by the material deforms when exposed to a magnetic subject. This deformation is straight proportional to your displacement or position of a magnet, letting these sensors to provide very precise measurements in a wide range of industrial and industrial apps. Magnetostrictive engineering is perfect for purposes demanding precision and durability in harsh environments, for example producing crops, oil refineries, and water therapy services.

Magnetostrictive liquid level meter are Probably the most frequent apps of the know-how. These sensors are utilized to evaluate linear displacement with exceptionally superior precision, making them perfect for checking the motion of equipment or other mechanical devices. They are generally utilized in automated programs the place exact placement feed-back is critical. The real key benefit of magnetostrictive displacement sensors is their non-contact measurement approach, which gets rid of don and tear on mechanical pieces, thus extending their lifespan and making sure consistent efficiency eventually. These sensors are also highly immune to environmental things which include dust, humidity, and temperature fluctuations, which makes them ideal for use in difficult industrial environments.

Magnetostrictive liquid level sensors are A further vital application of the technological know-how. These sensors are accustomed to measure the level of liquid in tanks, vessels, or pipelines, creating them essential in industries which include chemical processing, drinking water therapy, and oil and fuel. By utilizing a magnetostrictive sensor to detect the position of a floating magnet, the liquid amount might be measured with good accuracy. This know-how gives a reliable different to other liquid level sensing approaches like float switches or capacitance-based sensors, significantly in scenarios where by the liquid is highly corrosive or matter to superior pressures. Magnetostrictive liquid level sensors will also be well suited for applications in which Serious precision and long-phrase dependability are important.

Magnetostrictive posture sensors provide Yet another benefit in automated Manage and robotics methods. These sensors are utilized to trace the placement of shifting parts, such as robotic arms, linear actuators, or other mechanical parts. Magnetostrictive place sensors provide serious-time responses using a high standard of precision, making it possible for for specific Management more than mechanical devices. Their non-Speak to measurement method can make them really ideal for apps where by routine maintenance and downtime need to be minimized, and they could face up to vibrations, shock, and exposure to harsh chemicals, producing them perfect for an array of industrial and robotic applications.

The magnetostrictive liquid level meter, similar to the liquid amount sensors, is specifically made to evaluate the quantity of liquid within a container with Extraordinary precision. These meters are critical in industries that take care of significant quantities of liquids, including oil refineries, pharmaceutical manufacturing, and chemical plants. Magnetostrictive liquid amount meters offer numerous rewards, together with continual measurement, resistance to environmental contamination, and a chance to measure numerous liquid kinds, including viscous, corrosive, or high-temperature liquids. The accuracy and longevity of magnetostrictive technological know-how make sure the liquid degrees are monitored properly above long periods, furnishing worthwhile data for course of action optimization and safety monitoring.

In conclusion, magnetostrictive sensors—regardless of whether useful for displacement, position, or liquid level measurement—are crucial applications in modern day industrial programs. Their non-Get hold of measurement, high precision, and skill to resist harsh environments make them a most well-liked choice for a wide variety of industries, which includes production, automation, and liquid handling. As engineering continues to progress, magnetostrictive sensors will probable see even further innovation and come to be more integral in increasing precision and dependability throughout unique sectors.

Tatyana Ali Then & Now!

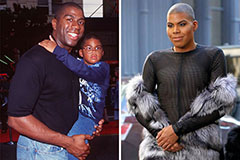

Tatyana Ali Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!